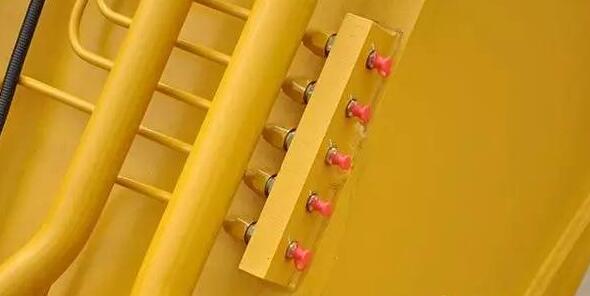

You are all directed at the nipple come in, but today is to say that the shape of the nipple on the excavator is a small thing, directly above, like not everyone please make up your brain.

The old driver should be able to see through it at the moment, this is the butter, and the link between the mechanical equipment of the butter mouth.

Butter, for you a friend, can be described as commonplace, every morning to go to the site, whether or not there will be out of the grease gun maintenance, this is the first step to become a good driver in china. Different brands and even the same brand of different types of grease nozzle position there may be different, but it was in the bucket 4 pin location and size of arm pin parts, bucket cylinder joints, arm cylinder joints, arm cylinder joints, rotary parts etc..  In addition, in order to protect the safety of large excavators and to improve the convenient maintenance process, the root of the arm with a centralized lubrication point, so you do not worry about the size of the arm pin pin less than butter! If it is a small excavator with a shovel, then push the shovel of the oil cylinder and the pin shaft connection must remember to add regular butter oh! Other working devices such as the hammer should also be two times a day lubrication, the tension of the device to see the operating conditions, if not meet the requirements should also be timely filling. In this case, the excavator nipple seems to be a little more. But if you want to be an old driver, the location of each nipple should be kept in mind and add butter on time!  It can be said that every excavator apprentice learning path is from the butter started, this sounds more "light" behavior can make every excavator work better. Why appears to be light, because playing butter are really hard work, some apprentice too tired and give up halfway, and finally become the master is also coming from butter. So why does the excavator need to beat butter? How often do you play? Is it possible to use gear oil instead? Today to show you! Why do you need butter?  The size of excavator at work on several ten arm and bucket position would move relatively, these parts of the pin and sleeve work has been undergoing friction, and because the excavator work load, these parts of the force is very large. "On an excavator bucket 4 pins need lubrication This is really real iron steel, so the intensity of work if allowed to dry grinding, shaft pin and Bush will be damaged seriously, in a few days the gap is very large, affecting the excavator work and maintenance high replacement cost. In order to reduce this part of the friction, the excavator is designed in these parts of the movement of the lubricant injection and retention channels, so that each of the two moving parts can be formed in the middle of the oil film, reducing wear. And this lubricant is butter. How long does it take to butter?  In order to let the excavator work better, each excavator are marked in each part of the time in the maintenance manual, and butter is generally working with a time interval of 5-8 hours, that is to say every day at work, at least need to add a butter. Centralized lubrication points on the 936E / Liugong excavator When the excavator took an apprentice, this work is completed by the apprentice, the size of the excavator arm and bucket on ten different positions of the lubrication points with each lubrication points are required to use the grease gun "pressure" for the eight or nine time in lubrication, so many positions every day to fight again really is individual life. Can you use gear oil or oil instead?  Some people may ask, why not use gear oil? It's just a good way to pour in, no butter. "From an excavator bucket cylinder grease pin out port In fact, this is due to the characteristics of the excavator, the working parts excavator are "low speed and heavy load, and the sealing performance is not good, if the use of liquid lubricating oil in the work is very easy to miss and cannot form a good oil film. Therefore, in front of the excavator working device shaft pin need to add grease, retained for a long time, and can be glued to each lubricating part of the formation of oil film, to maintain good lubrication. Finally, I would like to say that some of the advantages of the butter hit the excavator is really great, pin shaft and shaft sleeve wear rate will be much slower, these parts of the work gap is small. Excavator working noise and accuracy will be much better, so I want to say to those who are excavator apprentice let you play every day, really is not difficult for everyone in the butter, which is to learn basic skills of excavator, excavator ask even don't know how to cherish, how can learn harnessing this big guy, right! (责任编辑:admin) |